Coal Combustion Products

CCP SALES

As part of our commitment to sustainable energy solutions, Stanwell supplies hundreds of thousands of tonnes of coal combustion products (CCPs) each year to the construction industry — helping conserve natural resources and reduce the environmental impact of major infrastructure projects.

We are proud members of the Ash Development Association of Australia (AADA) and the Concrete Institute of Australia (CIA).

Our CCPs are available from both Stanwell Power Station (Central Queensland) and Tarong power stations (South Burnett).

Contact us for a discussion on how CCPs could benefit your business or project.

CCPs SalesCCPs OFFERED BY STANWELL

Coal combustion products are the collective term for fly ash, bottom ash or cenospheres – all generated during the combustion process at our power stations. Stanwell provides all three as sustainable alternatives to natural quarry materials:

1. Fly ash accounts for up to 90% of the CCPs produced at our sites. It is widely used in the manufacture of concrete and cementitious products, where it improves strength and durability while reducing the environmental footprint of traditional materials.

2. Bottom ash consists of larger particles that collect at the base of the boiler. It is used as structural fill, for road stabilisation and in pipe bedding. Stanwell is also partnering with industry to explore the performance of bottom ash in sustainable pavement design.

3. Cenospheres are naturally occurring, hollow spheres formed during the production of fly ash. With their ultra-low density, high compressive strength, pure white colour, and excellent thermal resistance, Stanwell’s cenospheres are used across a wide range of industrial applications, including ceramics, plastics, resins and paints.

These products reflect Stanwell’s broader sustainability approach – supporting circular economy outcomes, reducing environmental impact and delivering practical value to industry.

Trials in road design and construction

Road repair and construction are major infrastructure priorities across Queensland. Stanwell is working with industry to promote the reuse of CCPs in pavement applications and remove barriers to adoption. Key trials include:

2022: Road repair trial at Stanwell Power Station

Demonstrated efficient recovery, handling and placement of CCPs

Showcased standard dust management practices

2020: Intersection reconstruction at Stanwell Power Station

Delivered in partnership with ADAA and Capricorn Enterprise

Assessed CCP performance against State Road Authority standards

Demonstrated strong performance in both rigid and flexible pavement designs

Ongoing monitoring will contribute to a long-term case study

Stanwell also supports current studies by The National Asset Centre of Excellence, which is testing a range of recycled materials – including bottom ash – in greener pavement design.

Supporting fly ash off-take in the concrete industry

Fly ash is widely used to replace 20–30% of cement in concrete, reducing the energy intensity of production and lowering material-related emissions.

Stanwell actively collaborates with industry to increase fly ash uptake in infrastructure and building projects.

Our commitment includes the Tarong fly ash off-take facility, which can dispatch up to 400,000 tonnes of high-grade cement fly ash annually. Tarong CCPs have previously supported major projects including the Gateway Bridge Motorway Duplication, Clem7 tunnel, Airport Link Tunnel, City Link and the Go Between Bridge.

CCPs, circular economies and sustainability targets

Many of our clients are using CCPs as part of their circular economy strategies, helping reduce reliance on virgin resources and improve sustainability performance. These outcomes align with Stanwell’s goal to support our clients in their own sustainability journeys. CCPs offer measurable benefits across economic, environmental and operational indicators, including:

Conservation of natural resources

Energy savings and reduced material-related emissions

Cost and time efficiencies in construction

We work with our customers to help quantify these benefits and integrate CCPs into their building and manufacturing processes.

Learn more about beneficial reuse and the National Waste Policy.

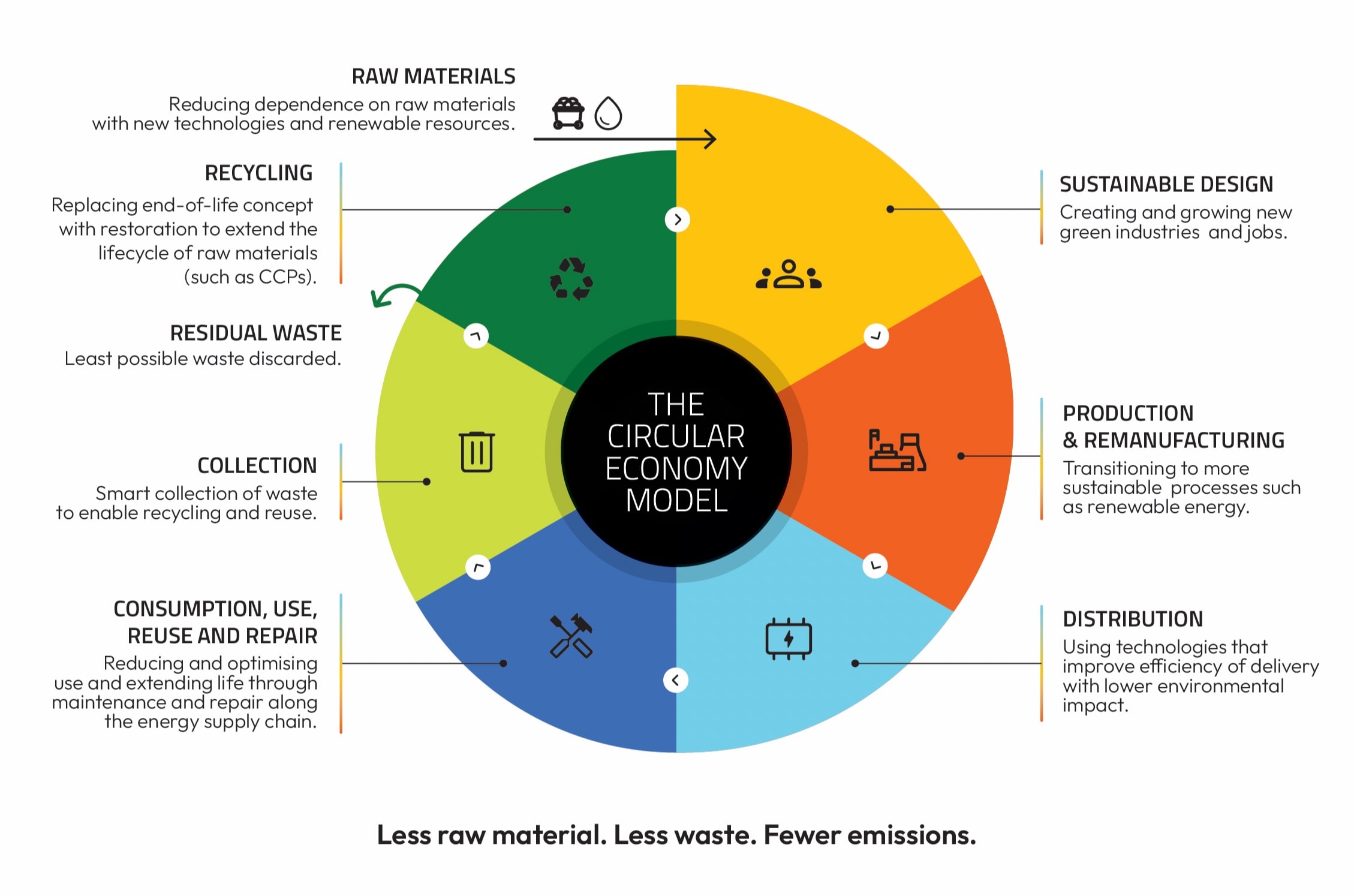

THE BENEFITS OF A CIRCULAR ECONOMY

A circular economy keeps materials in use through processes like maintenance, reuse, repair and recycling, helping reduce waste and enhance long-term resource efficiency.

Stanwell is committed to supporting circular outcomes by identifying and enabling beneficial reuse of coal combustion products.

The model below outlines the key elements of a circular system, and how Stanwell, as a major energy provider, plays a role in delivering these outcomes.